|

|

|

|

BendPak HD-7P 7,000-lb. Capacity Short Runways Extra-Tall ALI 4 Post Car Lift

To view the lift inspection guide

Click Here.

The HD-7P is a true space-saving powerhouse. The perfect service lift for shops with limited floor-space, the HD-7P requires no special foundation or complicated installation. About the size of a typical parking space, this lift doubles nicely as a residential / commercial parking lift. The applications are endless, but what else would you expect from BendPak? After being in this business for over 40 years, our reputation is as solid as our lifts. And if you've ever owned a BendPak, you know that means a whole lot.

Dependable design

4 heavy-duty, high-quality, stainless steel lifting cables and a single hydraulic cylinder mounted underneath the runway makes this lift the most durable, maintenance-free lifting system on the market.

Dual-hub cable sheaves

Reduce stress and fatigue on the axles, sheaves and cables. We insist on using dual-hub cable sheaves, even if they cost us more to make. When you buy BendPak, we throw in peace of mind as a free gift.

Multi-level locking positions

The HD-7P is equipped with multiple adjustable height locking positions for variable-height parking. A convenient push-button pneumatic safety lock control releases all four independent safety locks simultaneously.

Heavy-duty aircraft cable

Each lift is supplied with 4 high-quality stainless steel lifting cables, rated at 14,400 lbs. each. The combined rating of these cables is more than 822% of the maximum lifting capacity of the entire lift! And we make sure it looks tidy too-all lifting cables are fully enclosed within the lift structure itself.

Electric / hydraulic power system

We incorporate maintenance-free electric hydraulic power systems into each lift for ultimate dependability, and all controls are conveniently located within close reach.

Large base plates

10" x 12" base plates provide a solid foundation for the HD-7P.

Single hydraulic cylinder

Each lift is equipped with a single hydraulic cylinder, hidden away under the runway for minimum exposure and maximum reliable performance. Our industrial-grade hydraulic cylinders feature a single-piece, pilot fitted, machined steel piston, wrapped with specially designed, pressure loaded U-cup piston seals, backups and wear bands to virtually eliminate fluid bypass. The micro-smooth chrome-rod is machined from high-yield, ground and polished C-1045/50 micro-alloy steel and plated to a minimum of .001" diametrically, to ensure superior cylinder operation and life. The superior-design high durometer, mechanically-loaded rod seals make rod leakage is a thing of the past while a specially formulated abrasion-resistant urethane rod wiper provides exclusion protection. The welded cylinder body is made from robust steel tubing produced to exceed ASTM specifications. This combination of superb base material and superior processing ensures that the cylinders remain straight, smooth and last a very long time. An integrated flow restrictor provides a controlled descent in the case of an unexpected hose rupture.

Durable powder-coat finish

All HD-Series lifts feature a durable powder-coat finish that gives the metal a high-quality, extremely durable finish which can withstand even the harshest environmental or chemical conditions. Unlike other companies that claim to powder coat, we take pride in our meticulous 10-step process. First, all parts are visually inspected before being sandblasted. Afterwards, the parts are washed in our 5-stage phosphate tanks that can accommodate parts up to 25' long. Once cleaned, they're immediately dried to avoid rust production, and then outgassed. Outgassing pre-bakes the parts in a curing oven, reducing the possibility of blemishes that may be hiding in the pores of the metal. If not properly outgassed, imperfections in the metal may bubble during the curing process and most likely will cause chips in the powder. After the parts are washed and outgassed, any surfaces and / or threaded holes that need to be masked or plugged, are done so with high-temperature masking tape and silicone plugs. Next, the parts are given a quick thinner wipe to remove any light debris or fingerprints, before being hung on an electrostatically grounded conveyor line. The powder is finally applied using an electrostatic spray gun. The powder "sticks" to the surface in a fashion similar to how dust sticks to a television screen. Once the parts are powder coated, the carts are rolled into our curing oven and baked at 400° F for 45 minutes.

Caster kit

Optional 4-piece caster kit makes your lift portable, with or without car.

Integrated design

Lifting cables, airlines, safety latches and sheaves are all fully enclosed.

Low-deck runways

Our low 4-1/2" runways accommodate even the lowest cars.

Longer approach ramps

These approach ramps were designed a little longer to help when loading low ground clearance vehicles. It's the little bit that makes a big difference.

Automatic safety locks

Aircraft-quality stainless steel and aluminum pneumatic cylinders release all 4 locks simultaneously with the simple push of a button. The spring-loaded safety locks automatically engage continuously as the lift is raised. For added safety, a secondary lock system acts as a slack-cable device to engage in the unlikely event of cable failure.

|

Model

|

HD-7P

|

HD-7W

|

|

Style

|

Narrow Width

|

Wide Width

|

|

Capacity

|

|

Lifting Capacity: (*)

|

7,000 lbs. (3,175 kg)

|

|

*Max Capacity / Front Axle

|

3,500 lbs. (1,588 kg)

|

|

*Max Capacity / Rear Axle

|

3,500 lbs. (1,588 kg)

|

|

Rise

|

|

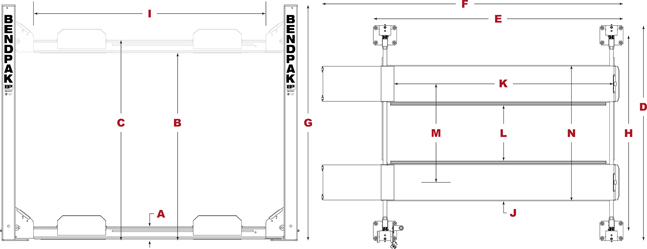

A - Min. Runway Height

|

4.5" (114 mm)

|

|

B - Max. Rise

|

82" (2,083 mm)

|

|

C - Max. Lifting Height

|

86.5" (2,197 mm)

|

|

Time to Full Rise

|

35 seconds

|

|

Outside Dimensions

|

|

D - Overall Width

|

100.25" (2,546 mm)

|

110.25" (2,800 mm)

|

|

E - Outside Length

|

174" (4,420 mm)

|

|

F - Overall Length

|

200" (5,080 mm)

|

|

G - Height of Columns

|

100" (2,540 mm)

|

|

Inside Dimensions

|

|

H - Width Between Columns

|

90.25" (2,292 mm)

|

100.25" (2,546 mm)

|

|

I - Drive-Thru Clearance

|

76.5" (1,943 mm)

|

86.5" (2,197 mm)

|

|

Runways

|

|

J - Runway Width

|

19" (483 mm)

|

|

K - Length of Runways

|

164" (4,166 mm)

|

|

L - Width Between Runways

|

37.5" (953 mm)

|

37.5" or 44.375" (953 or 1,127 mm)

|

|

M - Runway Centerline

|

56.5" (1,435 mm)

|

56.5" or 63.375" (1,435 or 1,610 mm)

|

|

N - Outside Edge of Runways

|

75.5" (1,918 mm)

|

75.5" or 82.375" (1,918 or 2,092 mm)

|

|

Minimum Wheelbase

|

|

Rated Capacity

|

115" (2,921 mm)

|

|

75% Capacity

|

100" (2,540 mm)

|

|

50% Capacity

|

85" (2,159 mm)

|

|

25% Capacity

|

70" (1,778 mm)

|

|

Locking

|

|

Locking Positions

|

15

|

|

Lock Spacing

|

Every 4" (102 mm)

|

|

Power Unit

|

|

Motor

|

220 VAC / 60 Hz / 1Ph

|

|

Noise

|

45 dB

|

|

Shipping

|

|

Weight

|

1,803-lbs. (817.8 kg)

|

1,702-lbs. (772 kg)

|

|

Dimensions

|

168" x 22" x 35" (4,267 mm x 559 mm x 889 mm)

|

166" x 22" x 34" (4,216 mm x 559 mm x 864 mm)

|

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

*Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV (Current Edition) or ANSI/UL 201. Consult

www.autolift.org for a complete list.

Click on Image to Download or Enlarge It

Better Products – Better Service – Better Value

LIMITED WARRANTY. Subject to the limitations of set forth below, Warrantor warrants that the Product sold hereunder conform to Warrantor's

published specifications. WARRANTOR MAKES NO REPRESENTATION OR WARRANTY OF ANY OTHER KIND, EXPRESS OR IMPLIED, WITH RESPECT TO

THE GOODS, WHETHER AS TO MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER MATTER

Duration: From the date of purchase by the original Purchaser or 60-24-12 months from the date of shipment by BendPak or whichever comes first.

- Five Years (60-Months) Warranty on the lift structure

- Two Years (24-Months) Warranty on the hydraulic cylinder(s) and power unit

- One Year (12-Months) Warranty on operating components

- One Year (12-Months) Warranty on electrical components (excluding power unit)

- One Year (12-Months) Labor Warranty on site or at factory*

- One Year (12-Months) Free-Shipping** on ground-freight charges related to warranty performance

Limited Warranty

- Who gives this warranty (Warrantor): BendPak Inc., 1645 lemonwood dr. Santa Paula, CA 93060

- Who receives this warranty (Purchaser): The original Purchaser (other than for purpose of resale)

- What products are covered by this warranty: Any BendPak Two-Post or Four-Post car lift***

- What is covered under this warranty: manufacturer defects due to material and/or workmanship with the exceptions noted below.

- What is not covered under this warranty:

- Any failure that results from Purchaser’s abuse, neglect or failure to operate, maintain or service product in accordance with instructions provided in the owner’s manual(s) supplied

- Any damage caused by overloading Product beyond rated capacity

- Items or service normally required to maintain the product, i.e. lubricants, oil, etc.

- Items considered general wear parts such as rubber pads, lifting cables, etc. unless wear or failure is a direct result of manufacturer defect due to material and/or workmanship

- Any component damaged in shipment or any failure caused by installing or operating lift under conditions not in accordance with installation and operation guidelines or damaged by contact with tools or surroundings

- Motor or pump failure caused by rain, excessive humidity, corrosive environments or other contaminants

- Rusted components due to improper maintenance or corrosive environments

- Cosmetic defects that do not interfere with product functionality

- Damage due to incorrect voltage or improper wiring

- Any failure that results from improper installation or use not according to specifications

- Damage caused by disasters such as fire, flood, wind, and lightning

- Damage caused by unauthorized attachments or modifications

- Responsibilities of Warrantor under this warranty: Repair or replace, at Warrantor’s option, component which is defective, has malfunctioned and/or failed to conform within duration of the warranty period. BendPak Inc. will pay reasonable labor costs for the first 12 months only

- Responsibilities of Purchaser under this warranty:

- Provide dated proof of purchase and maintenance records

- In some cases, components may be required to be shipped to the nearest BendPak Authorized Service Center. Freight costs, after 12-months, must be borne by the Purchaser.

- Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

- Immediately upon receipt of the Product, Purchaser shall inspect the same. Any claim for shortage must be made within ten days after Purchaser's receipt. All other claims, including claims for alleged defective Product, must be made within fifteen days after Purchaser learns of the facts upon which such claim is based, but in no event later than the applicable one, two or five year period specified above for the specified component(s). All claims not made in writing and received by Seller within the time periods specified above shall be deemed waived. With respect to any defects incapable of discovery until in use, all claims for any

damages or losses as a result of such defects shall be deemed waived unless made in writing and received by Seller within fifteen days after Purchaser learns of the alleged defect giving rise to the claim and after the expiration of said periods, but in no event later than the applicable one, two or five year period specified above for the specified component(s). Purchaser expressly assumes all liability for all such damages or losses, irrespective of any use which shall have taken place or whether the alleged defect shall have occurred or been discovered prior to expiration of such periods.

- When Warrantor will perform repair or replacement under this warranty: Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts.

*As determined by Warrantor in its sole discretion**Free-shipping applies to direct shipping points within the 48 continental United States.

Rural area shipping surcharge may apply for remote addresses. ***For all BendPak brand Two-Post or Four-Post Vehicle Service Lifts

(excluding specialty lifts, high rise, commercial parking, material handling, or models for particular purpose) manufactured on or following

1/1/2011.

https://bendpakcs.freshdesk.com/a/tickets/new

|

|

|

|

|

|

|

|

|

|

|

|

|

Features

- 7,000-lb. maximum lifting capacity

- High lift with short runways

- Runways include rail-kit for optional accessories

- Runways include outside guide rails

- Electric / hydraulic power system

- Single hydraulic cylinder mounted underneath runway

- Internal anti-sway slider blocks in each column

- Oversized self-lubricating cable rollers

- High-speed lifting

- Features heavy-duty 3/8" aircraft cable

- Rugged 1-1/4" roller axles

- Multi-position safety locks in each column

- Adjustable lock ladders

- Runways feature non-skid surface

- Push-button pneumatic safety release

- Optional 4,500-lb. capacity rolling jack available (Model RBJ-4500)

|

|

|

|

|

|

|

Owned & Operated in the U.S. since 1987

Owned & Operated in the U.S. since 1987